|

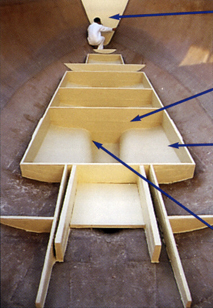

Integral Strength-Grid System™ |

|

|

Water-tight Collision Bulkhead heavily glassed in place bonded to the hull and the structural dividers forward of it. This creates an extremely strong matrix structure. |

| Integral tanks, lids, and baffles add strength to the subsole structure to help spread loads evenly over hull. Because the lids will be heavily bonded in place, any surface are of the tanks, will act to form a double-bottom. | |

| Structural sub-sole will be laminated around it's entire perimeter adding a complete bonding between grid structure and hull. Bonding all structures together. Keel, engine, and primary sea loads will be spread evenly over entire bottom surface area. | |

| Stringers are heavily glassed into position with extra heavy laminates and resins. Entire grid structure acts as a single strong unit. | |